机床介绍:

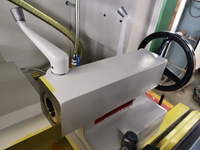

CAK系列数控卧式车床具有精度高、功率大、刚性高、等特点,其主要部件和结构均经过优化设计,是加工轴、盘、套、特形面及螺杆类工件的首选设备。

CAK series CNC lathe has the characteristics of high precision, high power, high rigidity, etc. The main components and structure are optimized design, is the preferred equipment for machining shaft, disc, sleeve, special surface and screw workpiece.

机床优点 Machine Advantages:

精密---高精度滑轨,高精密滚珠丝杆,高精度高刚性主轴轴承,激光干涉仪检测。

刚性——机床采用高强度铸铁,床身导轨宽度400mm,有效的提高了机床耐磨性及稳定性。

可靠——高性能数控系统,精确润滑系统,成熟结构设计。确保机床运行可靠,延长使用寿命。

安全——全封闭防护严防三漏,钢化玻璃安全窗,操作安全舒适。

High Precision —— High precision Guideway, high precision ball screw, high precision and high rigidity spindle bearings, laser interferometer detection.

High Rigidity —— The machine adopts high strength cast iron, the width of the bed guideway is 400mm, which effectively improves the wear resistance and stability of the machine.

Reliable —— High performance CNC control system, precise auto lubrication system, mature structure design. Ensure the reliable operation of machine, prolong the service lif

Safety —— Fully closed protection to prevent leakage, toughened glass safety window, to ensure safe and comfortable operation.

基本配置:

广数GSK980TDI系统

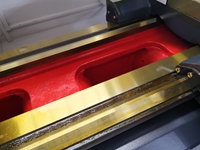

精密预拉伸滚珠丝杠

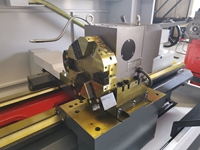

手动3爪自定心卡盘(10寸,12寸)

四工位电动刀架

手动尾座

变频主轴电机

自动润滑系统

自动冷却系统

全防护罩

Standard Accessories:

Controller:GSK980TDI

High precision pre-tension ball screw

Manual 3-jaw self-centering chuck (10” or 12”)

4T electric turret

Manual Tailstock

Frequency spindle motor

Auto lubrication system

Auto Cooling system

Full splash cover

可选配置:

FANUC、SIEMENS等其他系统

伺服电机

液压中实、液压中空卡盘

液压尾座

6工位、8工位电动刀架

送料机

Optional Accessories:

FANUC、SIEMENS or other brand controller

Servo Main motor

Hydraulic Solid / Hollow chuck

Hydraulic Tailstock

6T / 8T Electric Turret

Bar Feeder

|

Specifications |

Specifications |

CAK6140 |

CAK6150 |

CAK6161 |

CAK6166 |

CAK6180 |

||||

|

床身上最大回转直径 |

Max .Swing over bed |

400mm |

500mm |

610mm |

660mm |

800mm |

||||

|

刀架上最大回转直径 |

Max.Swing over carriage |

210mm |

300mm |

370mm |

400mm |

540mm |

||||

|

中心高 |

Center Height |

200mm |

250mm |

305mm |

330mm |

400mm |

||||

|

最大工件长度 |

Max. Work piece Length |

750/1000/1500/2000/3000mm |

||||||||

|

主轴孔锥度 |

Spindle taper |

MT6; (Φ90 1:20) [Φ113 1:20] |

||||||||

|

床身宽度 |

Bed width |

400mm |

||||||||

|

主轴通孔直径 |

Spindle bore |

52mm, (B:80mm), [C:105mm] |

||||||||

|

卡盘规格 |

Chuck Type |

C6; [D8 (B&C Type)] |

||||||||

|

主轴转速 |

Spindle speeds |

独立主轴无级变速Independence Spindle: 100-1600rpm 三挡变速3-steps speed change: 21-1500rpm (I 162-1500; II 66-500; III 21-150) |

||||||||

|

X向行程 |

X axis traverse |

250mm |

280mm |

300mm |

320mm |

400mm |

||||

|

Z向行程 |

Z axis traverse |

600/850/1350/1850/2850mm |

||||||||

|

X/Z向快移速度 |

X/Z rapid traverse |

4/6m/min |

||||||||

|

尾座套筒通孔 |

Tailstock center sleeve diameter |

75mm |

||||||||

|

尾座套筒行程 |

Tailstock center sleeve travel |

150mm |

||||||||

|

尾座套筒锥度 |

Tailstock center sleeve taper |

MT5 |

||||||||

|

定位精度 |

Positioning accuracy |

±0.015mm |

||||||||

|

重复定位精度 |

Repositioning accuracy |

±0.006mm |

||||||||

|

主电机功率 |

Spindle motor |

7.5kw |

11kw |

|||||||

|

包装尺寸 Packing dimensions |

750mm |

2550×1550×1770mm |

2550×1650×1900mm |

|||||||

|

1000mm |

2750×1550×1770mm |

2750×1650×1900mm |

||||||||

|

1500mm |

3250×1550×1770mm |

3250×1650×1900mm |

||||||||

|

2000mm |

3700×1550×1770mm |

3700×1650×1900mm |

||||||||

|

3000mm |

4700×1550×1770mm |

4700×1650×1900mm |

||||||||

|

净重/毛重N.W. / G.W. |

750mm |

2100/2800kg |

2120/2900kg |

2250/2850kg |

2300/2900kg |

2400/3000kg |

||||

|

1000mm |

2200/2900kg |

2240/3000kg |

2400/3000kg |

2450/3050kg |

2550/3150kg |

|||||

|

1500mm |

2300/3150kg |

2350/3200kg |

2600/3200kg |

2650/3250kg |

2750/3350kg |

|||||

|

2000mm |

2700/3350kg |

2740/3400kg |

2830/3400kg |

2880/3450kg |

2980/3550kg |

|||||

|

3000mm |

3500/4100kg |

3600/4250kg |

3650/4250kg |

3700/4300kg |

3800/4400kg |

|||||