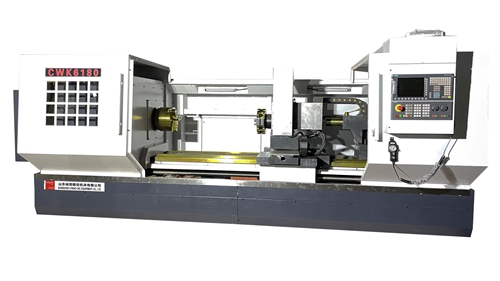

机床介绍:

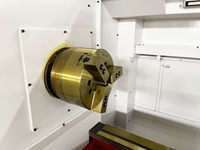

CWK系列重型数控卧式车床具有精度高、功率大、刚性高等特点,其主要部件和结构均经过优化设计。主轴系统结构采用四档变速,抗震性好,稳定性好,具有良好的切削性能。X,Z向滚珠丝杠由伺服电机直联驱动,动态响应优良,整机噪音低,对大、中、小批量,多品种、多规格零件的批量加工有较强的适应能力,加工质量稳定可靠。能够自动完成零件的内外圆、端面、切槽、任意锥面、曲面、公英制圆柱、圆锥螺纹等多种工序车削。加装动力刀塔后,可完成铣削,钻孔,攻丝等更多复杂加工工序。

CWK heavy-duty CNC lathe have the characteristics of high precision, high power and high rigidity. The main components and structure have been optimized. The main shaft system structure adopts 4-step speed transmission, good shock resistance, good stability, with good cutting performance. X, Z axis ball screw is driven by servo motor direct connection, excellent dynamic response, low noise, multi-specification parts of the batch processing has a strong ability to adapt to, processing quality is stable and reliable. Can automatically complete the parts of the inner and outer circle, end face, grooving, arbitrary conical surface, curved surface, male cylinder, taper thread and other processes. After install powered turret, the machine can finish milling, drilling, tapping and other more complicated processes.

机床优点 Advantage:

精密---高精度滑轨,高精密滚珠丝杆,高精度高刚性主轴轴承,激光干涉仪检测。

刚性——机床采用高强度铸铁,床身导轨宽度600mm 和700mm,机床床身采取整体床身设计,有效的提高了机床耐磨性及稳定性。

可靠——高性能数控系统,精确润滑系统,成熟结构设计。确保机床运行可靠,延长使用寿命。

安全——半封闭防护严防三漏,钢化玻璃安全窗,操作安全舒适。

High Precision —— High precision Guideway, high precision ball screw, high precision and high rigidity spindle bearings, laser interferometer detection.

High Rigidity —— The machine adopts high strength cast iron, the width of the bed guideway is 600mm and 700mm, machine body adopt integral design, which effectively improves the wear resistance and stability of the machine tool.

Reliable —— High performance CNC control system, precise auto lubrication system, mature structure design. Ensure the reliable operation of machine, prolong the service life

Safety —— Semi closed protection to prevent leakage, toughened glass safety window, to ensure safe and comfortable operation.